My visit to the old Golding factory 7/24/13

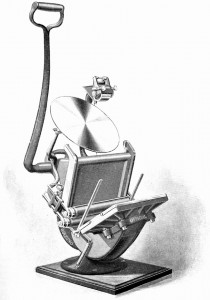

I had a very interesting adventure recently. I went to the old Golding manufacturing building in Franklin, Massachusetts located about an hour and 45 minutes from my home. This was the location they moved to from the Fort Hill section of Boston to gain more space in 1906. The building was the former Snow, Bassett Co. Straw Goods plant. It was an easy drive via route 6 through Rhode Island from my home in Lyme, CT. Driving on route 6 which is a really old road lined in some spots with failed or failing businesses got me in the right frame of mind for what I would find at my destination. As I pulled into the factory parking lot and looked at the large wood building in front of me, I could just imagine what it must have been like in Golding’s day. The massive smoke stack sending heavy smoke into the air from the casting process going on inside, to the hustle and bustle of loading the heavy presses at the loading docks. What a difference 100 years make. All was quiet this day. There were only a few cars in the parking lot, and as I walked inside I saw no people let alone a receptionist near the entry. I started walking up the stairs to see if I could find someone to talk to and could really feel the ghosts of the former businesses that occupied the building. The ceilings were tall and the creaking wood stairs were wide and lined with wainscoting that had been painted white too many times. I went up to the second floor but found no one, so I went up another floor. Still no one. One more floor and I saw someone behind a closed door that appeared to be a renter. He paid no attention to me so rather than disturb him, I decided to go back downstairs and try a different approach. Once on the first floor again, I heard voices and found a hall that lead into what I would say was the manufacturing area. I say this because it was a large, high ceiling industrial looking area that was dark, wet, and dirty. There I found two electricians working and asked where Kensol-Franklin was located. Kensol was the current building owner I was looking for. They make hot stamping presses used for applying foil to plastic items. I was directed up a back stair which one flight up opened into a nicer work area that was loaded with metal working machines. Out from a nearby office area came Paul, the gentlemen I had contacted. We exchanged pleasantries and then he lead me to a massive work bench to show me what we had talked about on the phone. It was a Golding Official No. 6 tabletop press in really nice condition. All of its parts were present, and it was on it’s original wooden board. Then, after I had admired it for a few minutes he ushered me across the room to another area and there on a dolly was another identical press. They are impressive tabletops with a chase size of 8-1/4 x 12-1/2 which is larger than the first Jobber in the line. Surprisingly, they are not the largest Golding made, but, I personally have never seen the largest model an Official No. 7 (10 x 15). Paul told me that their business had slowed to the point that they had sold the building and were in the process of cleaning out when these two presses were rediscovered. He then brought me into his office and showed me two printing plates.  The first one was a copper on wood halftone of an Official press. It was an image I had seen before and matches the image used in the 1908 Golding catalog and maybe some other years as well. The second one was an 11 pt brass plate of a Barnhart Brothers and Spindler ad for Golding equipment. It looked familiar as well, but, I am not sure where I may have seen it prior. It may have been in a copy of Inland Printer or an old printing machinery book which I read often. It does have a date on it of May 1st 1917. He also showed me some Golding cast iron case pulls that he had removed from a cabinet before it was discarded. After a little back and forth, we agreed on a price for the two presses, two plates, and 20 pulls. What a strange feeling. On July 24th 2013 I became the last customer to purchase a Golding press from the Golding factory. Yes, I did it almost 100 years after Golding ceased to exist, but, these two presses were manufactured in the same building, paid for in the same building, and loaded at the same loading docks as used by Golding and his employees when they were in business. In all likelihood, these two presses never left the premises. I further believe that at least one of them was being used as it was found complete with dried up rollers, packing, and tympan still on the press according to Paul. I cannot be sure which press company may have used it however. There were several that occupied the building after Golding. ATF purchased Golding in 1918 and continued to make the presses for about nine more years. Thomson National Company made the famous Colts Armory press there after that. And Kensol was part of the group that later owned Thomson. The plates were definitely from the Golding era, the presses more likely from the ATF time period. Neither press has the recurrent serial number faithfully applied by Golding on the top of the bed. That suggests to me they might have been ATF produced presses. As a Golding enthusiast, this was a pretty special day and I feel very fortunate to have had the experienced. Contact: john.falstrom@att.net

The first one was a copper on wood halftone of an Official press. It was an image I had seen before and matches the image used in the 1908 Golding catalog and maybe some other years as well. The second one was an 11 pt brass plate of a Barnhart Brothers and Spindler ad for Golding equipment. It looked familiar as well, but, I am not sure where I may have seen it prior. It may have been in a copy of Inland Printer or an old printing machinery book which I read often. It does have a date on it of May 1st 1917. He also showed me some Golding cast iron case pulls that he had removed from a cabinet before it was discarded. After a little back and forth, we agreed on a price for the two presses, two plates, and 20 pulls. What a strange feeling. On July 24th 2013 I became the last customer to purchase a Golding press from the Golding factory. Yes, I did it almost 100 years after Golding ceased to exist, but, these two presses were manufactured in the same building, paid for in the same building, and loaded at the same loading docks as used by Golding and his employees when they were in business. In all likelihood, these two presses never left the premises. I further believe that at least one of them was being used as it was found complete with dried up rollers, packing, and tympan still on the press according to Paul. I cannot be sure which press company may have used it however. There were several that occupied the building after Golding. ATF purchased Golding in 1918 and continued to make the presses for about nine more years. Thomson National Company made the famous Colts Armory press there after that. And Kensol was part of the group that later owned Thomson. The plates were definitely from the Golding era, the presses more likely from the ATF time period. Neither press has the recurrent serial number faithfully applied by Golding on the top of the bed. That suggests to me they might have been ATF produced presses. As a Golding enthusiast, this was a pretty special day and I feel very fortunate to have had the experienced. Contact: john.falstrom@att.net