My search for, and refurbishing of, a Merritt Gally Universal press

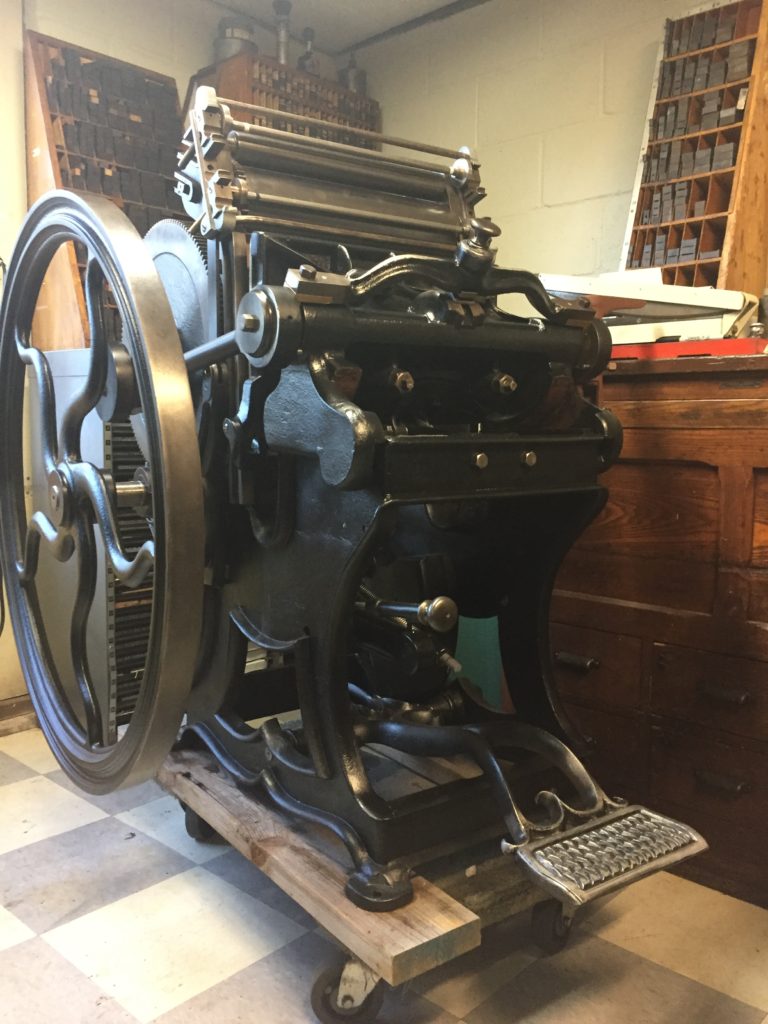

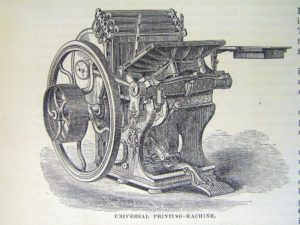

I have always wanted a parallel platen press from the day I discovered they existed. Those that are familiar with the concept know it is a significant improvement from a typical clamshell type press. The most famous was of course the Colt’s Armory press. Named after the manufacturer, Colt’s Armory in Hartford CT. When I first decided I was going to find one, it was that brand press that I sought out. I was thinking it should not be too difficult. I’m in CT. and have a lot of contacts. Boy, was I wrong. Being a Golding enthusiast and looking for Golding presses in New England was not difficult at all. I’ve now restored over 75 of them and still going. I passed up many as well. This type press was a whole different story. Vastly fewer numbers exist today, and those that own one don’t let them go very often. As I sought out more information about this class of press, I learned the story of how Merritt Gally was the first, and how he and John Thomson fought, and how Thomson ignored Gally’s Patents and began building a improved version of Gally’s original that we know as the Colt’s Armory press. I realized I liked the Gally press just as much as the Colt’s, but, it seemed even rarer.  What were the chances I could find one of those. It didn’t seem like good odds. Then, one day an ad appeared for a Gally Universal in Greenfield, MA. about two hours from my house. I went up to see it with great enthusiasm. It didn’t disappoint. It was a beautiful example of a 10 x 15 motorized Gally Universal. It had a few welds, but, beggars can’t be choosers. I told the owner I wanted it. That’s when I learned he was only taking bids. I had one shot. Give him a number, and if it was the highest, it was mine. He was keeping the bidding open for about a month as I recall. I offered what I thought was a good number. Well, I was not the winner. No recourse. It was gone. I was really disappointed. I continued to look, and after several years went by, I found another press in a local print shop very nearby in Essex, CT. This one was a Thomson Universal 13 x 19 without motor or treadle. It was huge, and not as attractive as the Gally I had missed earlier. I could not bring myself to bring this monster home. Just too darn big. I would continue my search for the perfect parallel platen press. Another year passed and a press I wasn’t aware existed was advertised on Briar press.

What were the chances I could find one of those. It didn’t seem like good odds. Then, one day an ad appeared for a Gally Universal in Greenfield, MA. about two hours from my house. I went up to see it with great enthusiasm. It didn’t disappoint. It was a beautiful example of a 10 x 15 motorized Gally Universal. It had a few welds, but, beggars can’t be choosers. I told the owner I wanted it. That’s when I learned he was only taking bids. I had one shot. Give him a number, and if it was the highest, it was mine. He was keeping the bidding open for about a month as I recall. I offered what I thought was a good number. Well, I was not the winner. No recourse. It was gone. I was really disappointed. I continued to look, and after several years went by, I found another press in a local print shop very nearby in Essex, CT. This one was a Thomson Universal 13 x 19 without motor or treadle. It was huge, and not as attractive as the Gally I had missed earlier. I could not bring myself to bring this monster home. Just too darn big. I would continue my search for the perfect parallel platen press. Another year passed and a press I wasn’t aware existed was advertised on Briar press.

It was a Hohner Din A4, 10 x 15 motorized press. As I researched it I began to realize this was a great opportunity. It likely is the most modern parallel platen available. It was made in 1979 and imported from Germany by The American Printing Supply Co. in NYC. It really seemed unique. I decided to make the purchase and had it shipped from CA. As is the case with many press shipments, it did not go well, and they did a great deal of damage to it. Fortunately, one of my good friends is a master machinist with just the right skill set combined with my skills to repair and restore everything that occurred during shipping. The restoration of the Hohner will be written up in a separate post.

Now that I had a really nice parallel platen press I thought I would stop thinking about that beautiful Gally press that got away. Well, I didn’t, and as luck would have it, I connected with Jim Macnab who runs the print shop at the Shaker Village in Canterbury, NH. He had been hunting for parts for a Gally Universal he was restoring for the Village. I kept seeing his name during my searches for a Colt’s/Gally press. Jim had an early example of a Gally, and he wanted me to buy it!  He had been restoring it when he was offered another Gally press that was in better condition. Jim had already done some of the preliminary work necessary to bring the press back. It was in the primer seen when I took over the restoration.

He had been restoring it when he was offered another Gally press that was in better condition. Jim had already done some of the preliminary work necessary to bring the press back. It was in the primer seen when I took over the restoration.

So, now I owned two, the Gally and the Hohner. The first and most likely the last parallel platen presses to be manufactured. This was going to be quite a project however. It had no means of propulsion( motor or treadle), and, it had many missing and broken parts. I didn’t care. It was beautiful, and I would take one step at a time and see what I could do. Another, really big help was that Jim loaned me some parts from his new press to help me recreate missing parts for mine. We did this over the winter when the Shaker Village was closed. During one of the many conversations I had with Jim he mentioned the frustration he was having because of the difficulty in treadling his press.  I mentioned I had a nice variable speed motor that might be fitted to his press and we both realized we wanted what the other possessed. A trade was done. My motor for his treadle. The treadle was originally on my press and now was to be reunited. The propulsion problem was solved. I tackled each problem and worked through what I thought was the best solution. New silicon bronze castings were made from the originals when needed. I use bronze rather than cast iron because I have a great relationship with Sher at the Mystic River foundry in Mystic, CT. They do not work with cast iron. Sher helped me immensely, and silicon bronze is a great material as it machines well and is not as brittle as cast iron. I needed to cast both feed and delivery supports. On the delivery side I didn’t have anything to go by for one needed piece so I carved a new one out of pine to use as a pattern for the casting. I visually copied what I could find in the few images available online. Another bit of good fortune provided four special 1/2-14 tpi screws needed to attach the new feeder and delivery brackets. A couple of years ago Ken Kulakowsky of the .918 Club brought me a Pearl to restore for his museum. With it was a small box of nuts and bolts he thought went with the Pearl. They didn’t, but, they were old so I saved them. In that box were four odd screws with the special thread that I needed for the Gally. The exact number, the correct length, and the correct rare thread. 1/2” bolts usually have 13 tpi, not 14 tpi. I needed feed and delivery boards to be made and again as luck would have it, a good friend, Don Gerber came to me to get some letterpress business cards for his wood turning hobby. I suggested we barter each others services. I printed his business cards, and he fabricated the needed boards including the little drawer on the feed board. He purchased an old oak furniture piece and used parts of it to make the boards look authentic. As seen in the following pictures, several other parts were repaired by brazing. You can see the gold metal shaped to it’s original contours.

I mentioned I had a nice variable speed motor that might be fitted to his press and we both realized we wanted what the other possessed. A trade was done. My motor for his treadle. The treadle was originally on my press and now was to be reunited. The propulsion problem was solved. I tackled each problem and worked through what I thought was the best solution. New silicon bronze castings were made from the originals when needed. I use bronze rather than cast iron because I have a great relationship with Sher at the Mystic River foundry in Mystic, CT. They do not work with cast iron. Sher helped me immensely, and silicon bronze is a great material as it machines well and is not as brittle as cast iron. I needed to cast both feed and delivery supports. On the delivery side I didn’t have anything to go by for one needed piece so I carved a new one out of pine to use as a pattern for the casting. I visually copied what I could find in the few images available online. Another bit of good fortune provided four special 1/2-14 tpi screws needed to attach the new feeder and delivery brackets. A couple of years ago Ken Kulakowsky of the .918 Club brought me a Pearl to restore for his museum. With it was a small box of nuts and bolts he thought went with the Pearl. They didn’t, but, they were old so I saved them. In that box were four odd screws with the special thread that I needed for the Gally. The exact number, the correct length, and the correct rare thread. 1/2” bolts usually have 13 tpi, not 14 tpi. I needed feed and delivery boards to be made and again as luck would have it, a good friend, Don Gerber came to me to get some letterpress business cards for his wood turning hobby. I suggested we barter each others services. I printed his business cards, and he fabricated the needed boards including the little drawer on the feed board. He purchased an old oak furniture piece and used parts of it to make the boards look authentic. As seen in the following pictures, several other parts were repaired by brazing. You can see the gold metal shaped to it’s original contours.

-

Silicon bronze castings -

Feed board -

Brazed support -

Delivery support -

Delivery board -

Brazed chase latch -

Repaired chase latch -

Special thread screws

There was no chase with the press so we shaved off 50 thousandths from a C & P 10 x 15 chase and repaired the break. It fits perfectly. That trick came from Jim Macnab. The roller trucks were missing and by a stroke of good fortune a perfect set was found at John Barrett’s Letterpress Things. John and I were both amazed at the find, but, that’s what happens when you dig around in his vast letterpress store. You find letterpress things.

-

Brazed repair of the chase -

Roller trucks

In addition to repairing broken parts and casting replacement parts, new parts needed to be fabricated outright. The first was a new roller saddle out of a block of steel. The press is supposed to have six, and mine came with five. This was a job for my machinist, Rich Sutton. What he fabricated is as good as the originals. Even more difficult was creating a oscillating roller. It had to be done from scratch also. I designed it to utilize the worm and dog from a modern offset press. This way if the worm and dog that causes the oscillation wear out, they can easily be replaced. The actual fabrication was again, a job for Rich. He did not disappoint.

-

Original roller saddles (bent) -

New roller saddle -

Oscillation roller detail -

Oscillating roller

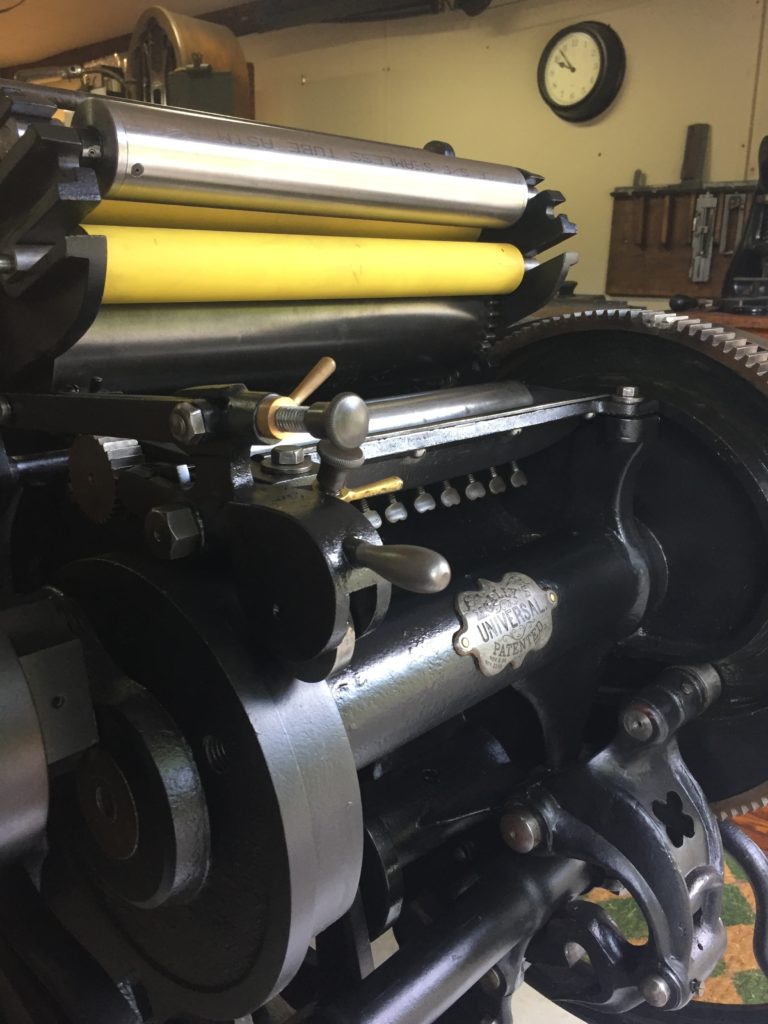

So the press is coming along really well. One thing that was on my wish list that was proving to be very difficult was finding an ink fountain. Few people use an ink fountain today, but, It just looked like something was missing. I wanted it for those aesthetics. Enter Jim Macnab once again. He had a beautiful fountain that came with his new press and graciously was willing to do another trade this time for some parts for his Golding presses he needed. Without Jim none of this would have been possible.

-

Merritt Gally Universal fountain

So now the press is complete except for getting the rollers covered. It has responded so well, that I have decided to take it all apart again and rebuild the worn drive parts, so that it functions as well as it looks. Jim Macnab had already replaced some large pins that were severely worn, but, there is still a number of areas that are in need of help.

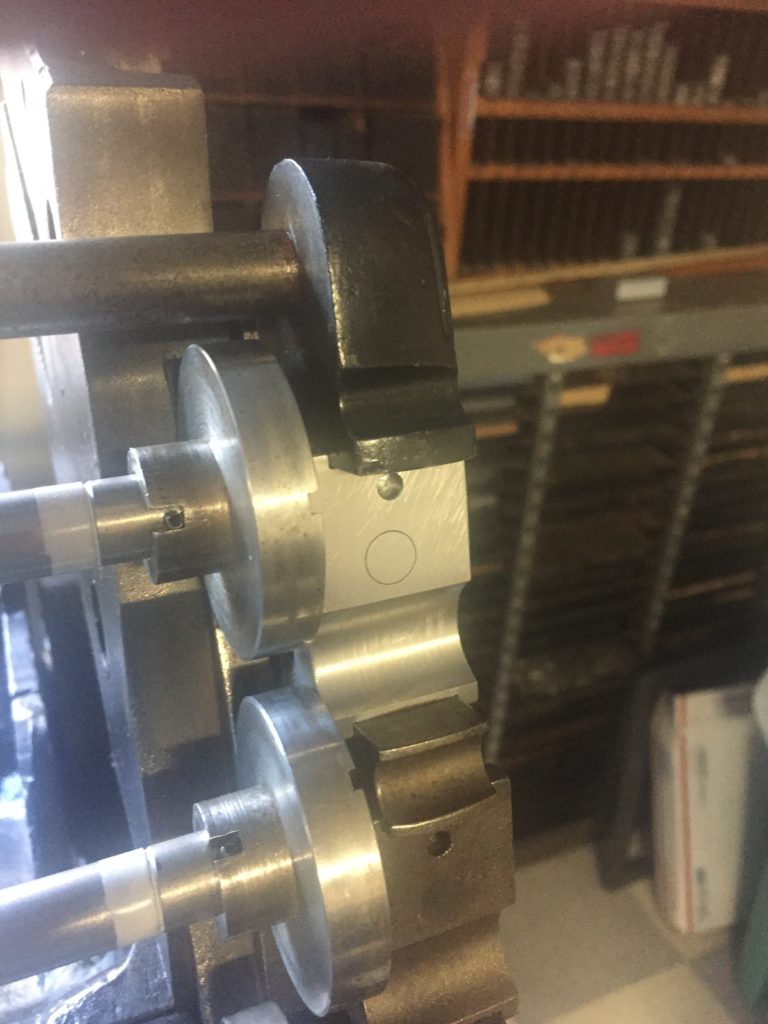

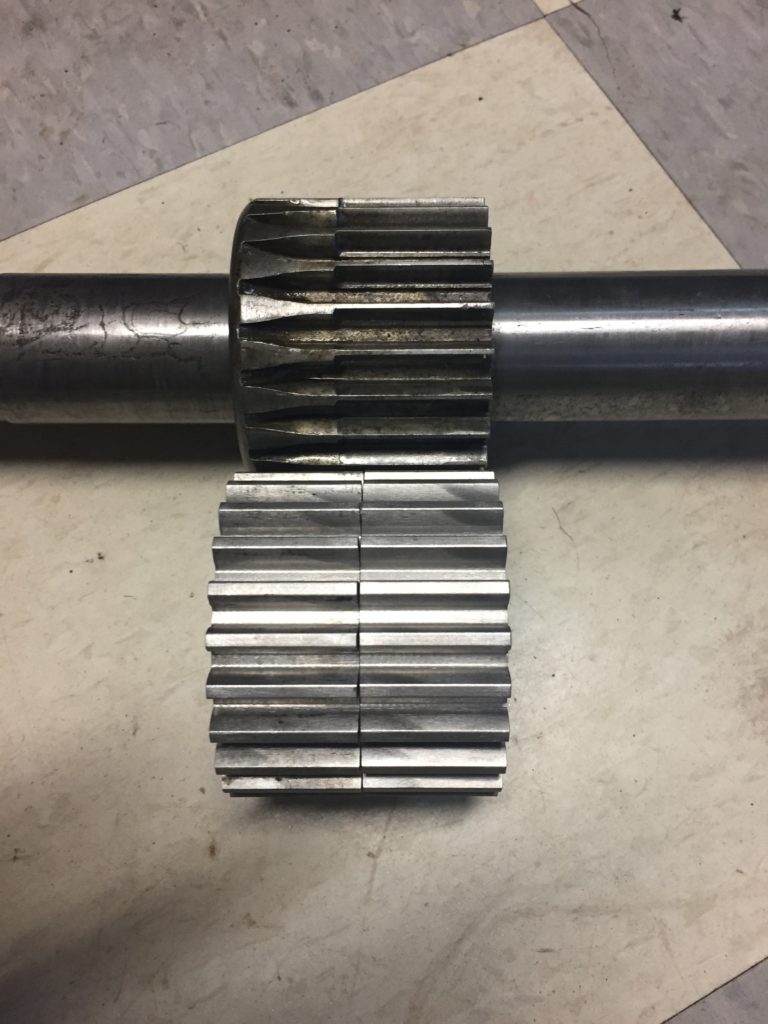

I didn’t do it originally because I was not at all sure I could find or make what I needed to complete the press. I thought it may just be a looker. Now, unbelievably, it is complete, and I know it can do what it was intended to do. With that in mind, it deserves the time and money to complete the job right. So, here we go again. First and most obvious is the worn pinion gear. Rich will turn down the existing gear as it’s part of the shaft, and install two new gears connected together side by side, and key them to the area where the original gear was. We’re using two gears because of a $2100 cost savings. One custom gear vs two stock change gears. If you look at the gear pictures you’ll see that the two stock gears put together are the exact width of the original gear. How much more luck will I have? Feels like I’ve already had more than my share. After the gear replacement I’ll assess the tightness of the press. I have identified several other potential spots that may benefit from replacing parts that are out of what I consider to be good tolerances.

-

Original worn gear -

Two new spur gears -

8 dp, 23 tooth, 14.5 pa gears

To be continued……